Plastic extruder and Auxiliary

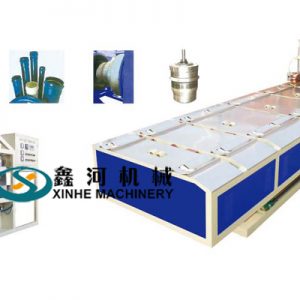

Haul-Off Unit Series

Caterpillars Haul-off unit, Three Caterpillars Haul-off unit, Four Caterpillars Haul-off unit, Six Caterpillars Haul-off unit, Eight Caterpillars Haul-off unit, Ten Caterpillars Haul-off unit, Twelve Caterpillars Haul-off unit, Pipe haul-off unit, Plate Haul-off unit, Sheet Haul-off unit and Profile haul-off unit.

Features and application:

Combined with plastic extruder,can be used for plastic tubular or shaped material Hauling and setting depend on customer’s demand.

This machine adopts double-caterpillar traction way and SCR(silicon controlled rectifier)stepless speed regulation It is mainly used with plastics extruder to extrude and draw plastic pipe ,special shaped materials, soft pipes and other kinds of shaped material. It is widly used in application and convenient in operation.

Adopting double-caterpillar traction way,wide application;

Adopting stepless speed regulation,large extent of speed regulation;

Even drawing speed;

Low noise;

Compact structure, fine appearance.

Pipe Belling Machine

expander with drawing device and program interface is used with extruding machine.It is also used solitarily,While expanding pipes,the machine adopts translation,The action is steady and corret,It does not damage pipe materical,The machine adoptes double-infrared heating oven type,Each oven is equipped with heating cire,The shaping method adopts expanding-end shaping, The size of pipe mouth is correct.On its panel,there is a transfer swith of expanding solvent type pipe socket(Straigh port)and expanding sealloop type pipe socket(Rport).The choice of expanding pipe type is very convenient, The technologocal adaptability is strong,Its main electric control elements are all imported.The syetem charecteristics are steady and reliable.

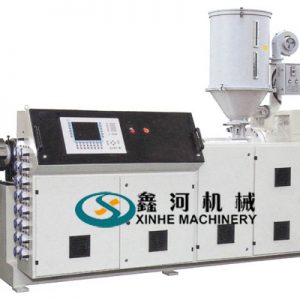

SHJ Series Parallel Twin Screw Extruder

Features and application :

Parallel twin-screw extruder is a kind of high-efficiency mixing, smelting, and extruding all-in-one equipment. Its core section is composed of “oo” type barrel and two gearing screws, matching with driving system, control system, and feeding system to form a kind of special extruding, graining and shaping processing equipment. The screw and barrel adopt building type design principle to change the length of the barrel, choose different screw stem parts to assemble the line according to material characteristics, so as to get the best work condition and max function. Because it has good mixing, separating, dewatering and self-cleaning functions to avoid the materials wrapping the axle, caking in the extruding process. With the rotation of the screw, the surface of the materials continuously change, helps the volatile matter dewater, treat, and etc.

SJ Series Single Plastics Extruder

Description:

Main Technical Parameter

Application:

The extruder can be used for extruding thermo-plastics such as PVC, PP, PE, PP-R, ABS. Combined with the appropriate auxiliary machinery(including the die head), it can used to produce many kinds of plastic products such as film, pipe, board, thread, tape, as well as granule.

Characteristic:

Suitable for various polyolefin materials: HDPE, PPR, PP, ABS, and PMMA, etc. Adopt advanced human-machine interface control system to realize the automatic control of the whole line.

Excellent temperature control system to ensure the stability of the manufacturing process. Integrated design of force water cooling and force feeding groove ensures the evenness and stability of the manufacturing process.

We provide turnkey project and perfect after-sales service. Welcome you to visit our factory for inspecting and business talking.

SJSZ Series Conical Twin-Screw Plastics Extruder

Features and application:

SJSZ series conical double screw plastic extruders are special equipments which can extrude and mold by using various kinds PVC powders. Equipped with different kinds of molds and auxiliary machines, it can produce various PVC pipes, profile, sheets, plates, bars and granulation.