Plastic pelletizing line

PE、PP waste film recycling and pelletizing line

2. Double-column online screen exchanger with larger filtering area.

3. Water ring granule cutting avoid material staining.

PET pelletizing line

Feature: This line is used for pelletizing PET, PP, PE, PS,PVC, and other engineering plastics

PVC hot-cutting pelletizing line

|

Main Technical Parameters

|

||

|

TYPE

|

SJZ65

|

SJZ80

|

|

INSTALLED POWER

|

90kw

|

100kw

|

|

OUTPUT

|

280kg/h

|

350kg/h

|

|

GRANULE DIAMETER

|

3mm

|

3mm

|

|

LINE LENGTH

|

15m

|

15m

|

Single Screw Pelletizing Line

Introduction of products:

The production line is the ideal equipment of plastic granulation, especially for PP, PE, ABS, PS sheet, HDPE, PP solid broken material recycling and granulation. The production line has the advantages of novel design, reasonable structure, stable operation, low noise, low energy consumption and high yield etc.. Vacuum exhaust or natural exhaust port design can exclude the waste gas and discharging water in the production process, which can be more stable in extrusion, more dense particles, and guarantee the good quality of the product.

Characteristics:

1: The efficient forced feeding ensures high feeding and low energy consumption.

2: It equipped with a special design of the barrel and screw and single screw exhaust system, can ensure high yield.

3: The cutting system adopts extrusion die head water ring to cut, which can ensure the perfect appearance of particle.

4: The auxiliary machine has the particle cooling and grading machine.

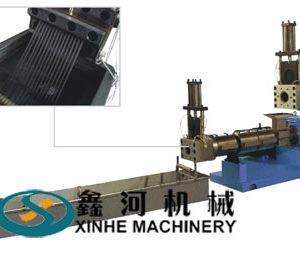

Twin Screw Pelletizing Line

The line adopts extrusion and hot cutting, applied to PP, PE plastic granulation. It features in advanced production machines, wide usage for general purpose, high productivity.

|

TYPE

|

L/D RATIO

|

SCREW ROTATION SPEED

|

INSTALLED POWER

|

OUTPUT

|

|

SJSL-20

|

28-40

|

600

|

5/5.1/7.5

|

5/20

|

|

SJSL-36

|

28-48

|

30/400/500

|

11/15/22

|

30/100

|

|

SJSL-51

|

24-52

|

50/500

|

37/45

|

80/180

|

|

SJSL-60

|

28-48

|

300

|

45/55

|

120/250

|

|

SJSL-63

|

32-52

|

400/500

|

55/75

|

150/400

|

|

SJSL-75

|

28-48

|

400/500

|

90/110

|

300/550

|

|

SJSL-92

|

32-48

|

400

|

250/280

|

750/1200

|

Two-stage cable pelletizing line

FEATURE AND FUNCTION:

The line adopts extrusion and hot cutting, applied to PVC plastic granulation. It features in advanced production machines, wide usage for general purpose, high productivity.

Two-stage recycling and pelletizing machine group

2. Good process ability for materials containing much water and impurities.

|

Main Technical Parameters

|

||||

|

TYPE

|

L/D RATIO

|

PELLETIZING WAY

|

APPLICABLE MATERIALS

|

OUTPUT

|

|

120/130

|

16-40/1

|

Water cool strand pelletize or Water ring die-face hot pelletize

|

PET,PE,HDPE bottle flakes,PE,PP membrane,ABS,PA etc.

|

200-300

|

|

130/150

|

300-400

|

|||

|

150/180

|

450-550

|

|||